Wire Cut EDM & CNC machining

Wire EDM and CNC Machining: Precision Tools for Modern Manufacturing

In the realm of modern manufacturing, precision and versatility are paramount. Two advanced technologies, Wire Electrical Discharge Machining (Wire EDM) and Computer Numerical Control (CNC) machining, stand as cornerstones for creating complex, high-accuracy parts. While both are controlled by digital instructions and are essential in sectors like aerospace, medical devices, and tool and die making, they operate on fundamentally different principles and are suited to distinct applications.

CNC Machining: The Art of Subtractive Manufacturing

CNC machining is a broad term for a subtractive manufacturing process. A block of solid material, typically metal, plastic, or wood, is selectively carved away by a rotating cutting tool (like an end mill or drill bit) to achieve the desired shape. The tool paths are controlled by pre-programmed computer software (G-code), allowing for highly repeatable production of parts with excellent dimensional accuracy. CNC milling and turning are the most common types. This method excels at creating 3D contours, pockets, threads, and complex geometries from a wide range of materials. Its strengths lie in its material versatility, excellent surface finishes, and efficiency for both prototyping and medium-volume production.

Wire EDM: Precision Through Electrical Erosion

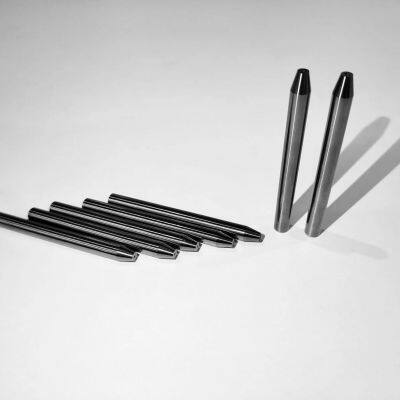

Wire EDM, a specialized subset of Electrical Discharge Machining (EDM), uses a different approach entirely. Instead of a physical cutting tool, it employs a thin, continuously fed brass or coated wire (as fine as 0.02 mm) as an electrode. The wire and the conductive workpiece are submerged in deionized water. A controlled electrical spark, generated between the wire and the material, creates an intense heat that melts and vaporizes microscopic particles of the workpiece. The dielectric fluid then flushes away the debris. This process is non-contact, meaning there is no mechanical force exerted on the part.

Wire EDM’s supreme capability is achieving exceptional precision and producing intricate shapes that are impossible or impractical for CNC cutting tools. It can cut extremely hard, conductive materials (like hardened tool steel, titanium, or carbide) with ease, as the hardness of the material does not affect the cutting speed. It is the go-to method for creating sharp inside corners, delicate features, and complex profiles in stamping dies, extrusion dies, and medical components. However, it is generally slower than CNC milling for bulk material removal.

Complementary Forces in the Workshop

In practice, these technologies are not competitors but powerful allies. A common workflow involves using robust CNC machining to create the initial part shape from a rough blank, followed by Wire EDM to achieve the final, intricate details or to cut the part from the block with ultra-fine precision. This synergy allows manufacturers to leverage the speed and strength of CNC with the unmatched accuracy and hard-material capability of Wire EDM.

Ultimately, the choice between Wire EDM and CNC machining depends on the part’s material, geometry, required tolerances, and production volume. Together, they form an indispensable duo, pushing the boundaries of what is manufacturable and enabling the innovation that drives advanced engineering forward.

Hefei Kaixin Precision Technology Co., LTD.

Tel:+86 18205608665